Products

Product description

|

Seal Manufacturing Systems |

|

|

Complete turn-key CNC Seal Manufacturing Systems |

|

|

UTEC Sealing Solutions offers you the latest technology in CNC machining systems, state-of-the-art computer technology and seal production software as well as high-performance sealing materials – the complete solution for modern seal production up to 1500mm OD. UTEC CNC lathes are custom-made, fully integrated systems, for the instant production of various seals used in hydraulic and pneumatic applications, as well as engineered plastic parts. Machine, software, semi-finished materials and tools are precisely tuned to guarantee efficient machining and top-quality products. Lathe-cut seals gain an ever-increasing market share in today´s sealing industry and are widely accepted in OEM and MRO applications — UTEC Sealing Solutions contributes its part to the success of this manufacturing technology. |

|

|

High-end Technology |

|

|

The machines are based on custom-designed lathes for metal machining and are modified and upgraded in our factory with all the features necessary for the machining of seals and plastic parts. All machines are equipped with high-end mechanical and electrical/electronic components. The high precision guides, disc turret, bearing, drive systems and control unit are without exception produced by world-wide, well-known brands who define the standards of modern CNC machining technology. These top-quality components in combination with a sturdy machine design guarantee a long service life of UTEC Seal Manufacturing Systems.

In order to guarantee the smooth operation of your UTEC CNC lathe, our customers will receive training on their machine, in our factory. After technical acceptance of the machine, it will be commissioned and installed on site by one of our engineers. |

|

|

Technical Features |

|

|

UT400E

|

|

|

Machine Components |

|

|

Control & Drive System

Tool System UT400E

Tools & Holders

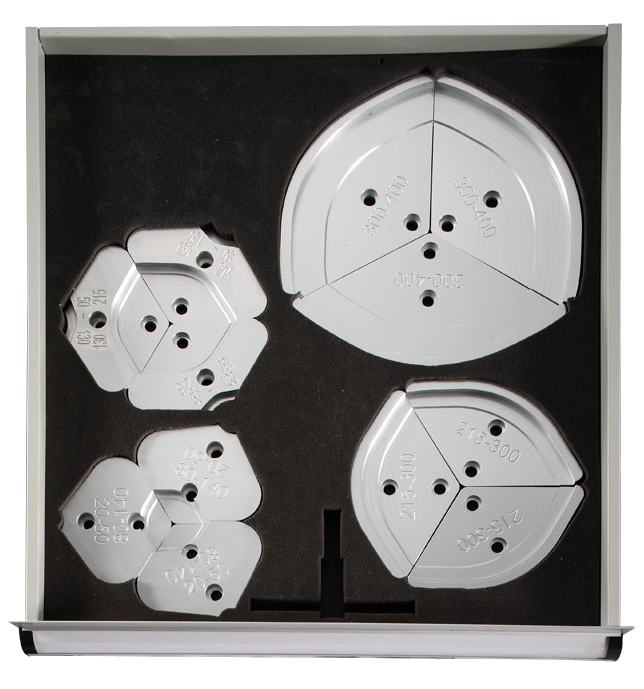

Material Clamping System

Chip Cutter & Suction Unit The chip cutter is made of high-grade aluminum, using HSS tools to hack up the chips and keep the tools clean for optimal machining performance.

Optional Accessories Other accessories, such as measuring devices, bevelling shears, band saws for cutting guide rings etc can be supplied on request. |

|

|

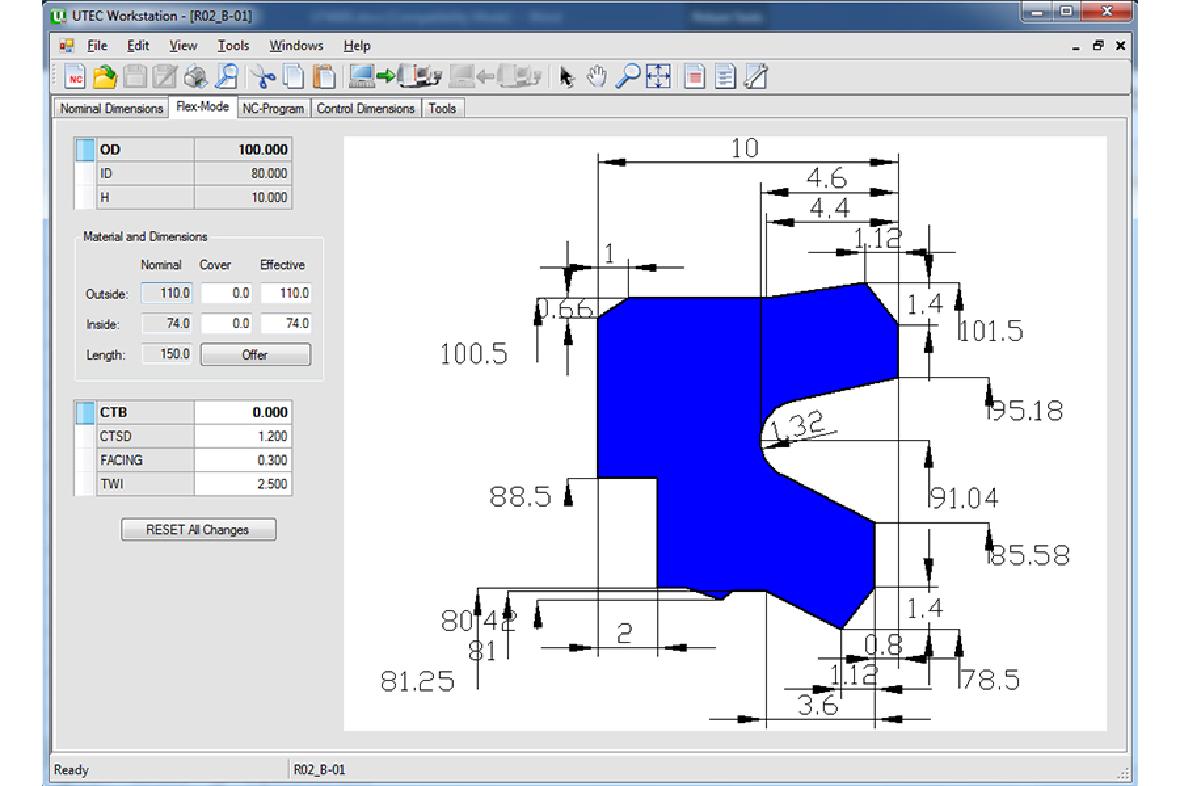

UTEC “Flex” Software |

|

|

The production software is developed in-house by UTEC engineers and underlies continuous updates, upgrades and improvements. Each of the more than 180 standard profiles can be easily modified by the user in the "Flex Mode" without the need to make modifications to the NC program itself.

The production process for seals is fast and easy: This way, and endless number of seal profiles and dimensions can be manufactured. This is what makes lathe-cut seal manufacturing technology the most versatile in seal business. |

Previous article:T1124

Next article:T1123